IPC-DPMX (IPC-2581) Consortium

IPC Digital Product Model Exchange

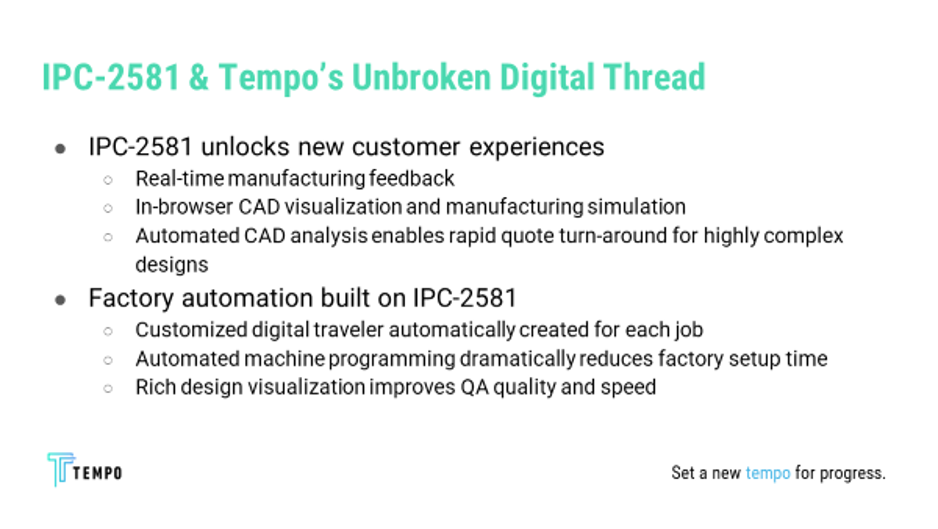

An open, global, BIDIRECTIONAL standard for efficient PCB design data EXCHANGE

Why IPC-DPMX

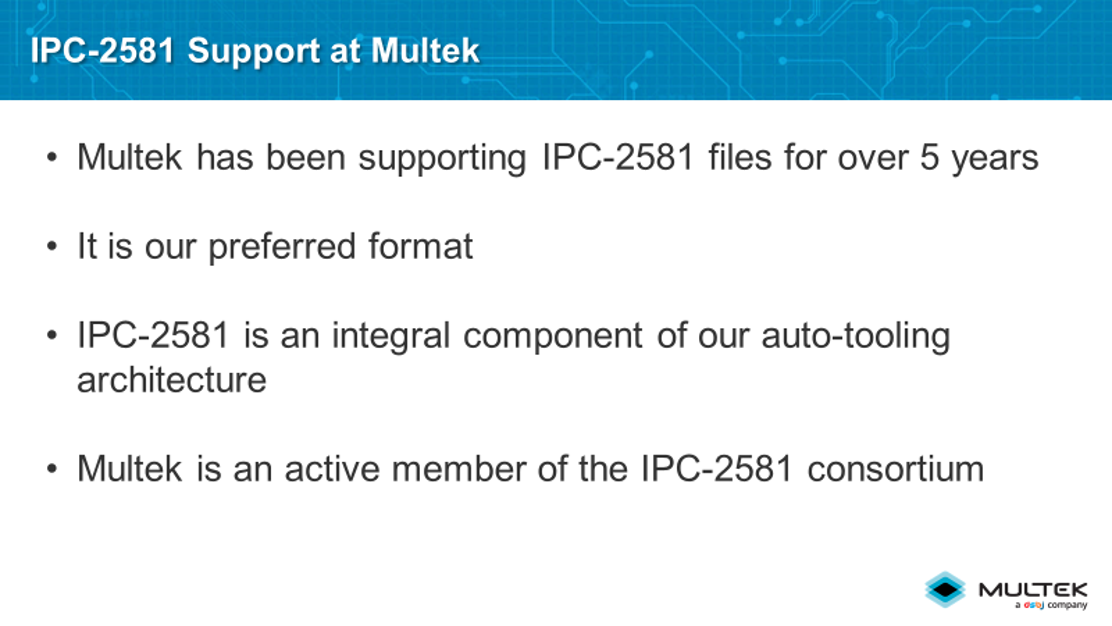

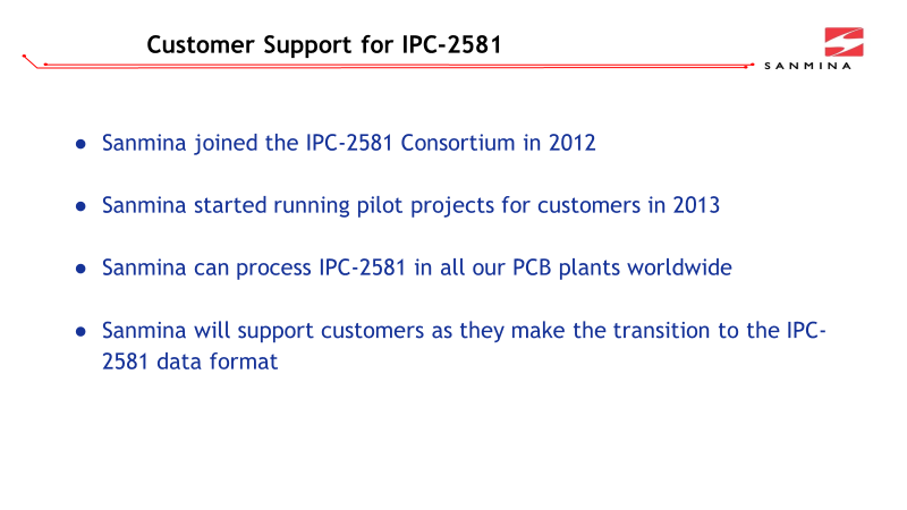

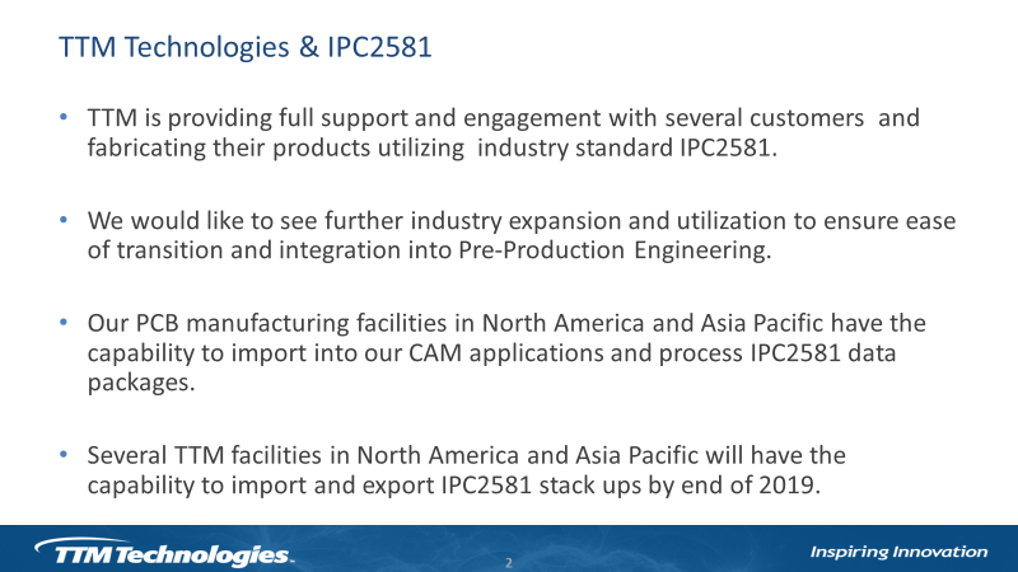

IPC-DPMX (Digital Product Model Exchange), also known as IPC-2581 is a generic standard for printed circuit board and assembly manufacturing description data and transfer methodology. Developed in 2004 by IPC, IPC-DPMX is used for exchanging information between a printed circuit board designer and a manufacturing or assembly facility. For nearly every step in the industrial process flow, IPC-DPMX offers a standard to help companies ensure superior manufacturability, quality, reliability and consistency in electronics assemblies built for their products.

Who We Are

IPC-2581 Consortium is a group of PCB design and supply chain companies whose collective goal is to enable, facilitate and drive the use of IPC-2581 in the industry. It is devoted to accelerating the adoption of IPC-2581 as an open, neutrally maintained global standard to encourage innovation, improve efficiency and reduce costs.

Join IPC-2581 Consortium Today Join Us

Download Free Viewer

Download free viewers from consortium members to view IPC-2581 data files

Download Test Cases

Download Test Cases to see the advantages of using IPC-2581 files by yourself